Wire spring according to europe norms ISO 10243: 2010 – square croos-section of wire, according to Japanese norm JIS B5012 , according to US norm – oval wire cross section. Springs according to customer’s dimensions.

more information

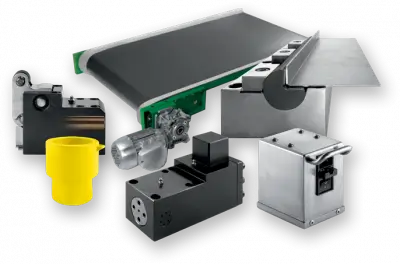

Meet the most stringent safety standards of the automotive industry. Equipped with five patented safety systems. According to ISO 11901-1, VDI 3003, B2 4006 BMW , 075.90.55 FCA , W-DX35-6203 Ford , PG23D Mazda , B8 3180 220 000 001 MB , K 32 S ( K32D2-2400-50 ) Nissan , E24.54.815.G PSA , EM24.54.700 Renault , SES-K 5404e Suzuki , 39D 878 VW , SMS DNH 3203n Rev.3 TOYOTA

more information

Two types of material – ADIPOL in hardnesses 72, 80, 90, 95, 98 Shore. Lifetime approx. 400.000 strokes. ULTRAFLEX in hardnesses 82, 92, 94 Shore. Lifetime approx. 800.000 strokes. Each hardness is in a different material colour.

more information

Pillars, bushes, ball cages, self-lubricating wear plates, bushings, guiding stripes, bar, L-Gibs, cam bottom plates. Sintered plates, bushings

more information

Transport pins, lifting brackets. Locating blocks, air pins, gages, locating cones, pressure plates, stamp retainers, spacing bars, roller stock lifters, slide stop blocks. Standard components by norms – Daimler (Mercedes, Smart), FCA (Alfa Romeo, Dodge, Fiat, Chrysler, Jeep, Lancia, Maserati), Ford, Geely (Geely, Volvo), GM (Buick, Cadillac, GMC, Chevrolet), Hyundai (Hyundai, Kia), Nissan (Datsun, Nissan), PSA (DS Automobiles, Citroen, Opel, Peugeot), Renault (Dacia, Renault), TATA (Jaguar, Land Rover, TATA Motors), Volkswagen Group (Audi, Bentley, Bugatti, Lamborghini, Man, Porsche, Seat, Škoda, Scania, Volkswagen) dle norem ISO, VDI, DIN, NAAMS, AFNOR, JIS, IATF.

more information

“Safety” is the motto of lifting and transport components. The offered range is able to fully satisfy all requirements in the field of press tools and moulds of all sizes and weights in maximum safety. The EC marking required by Directive 2006/42/EC for all manufacturers of “Transport and Lifting Components” requires many documents including use and maintenance manuals and conformity certification.

more information

Tapping units with mechanical drive and with electronic drive. A wide range of applications for threading in tools and special applications on lines. In the case of electronic tapping units, the individual parameters are set via computer. Torque monitoring of the tapping unit. Lifetime monitoring. Setting the number of turns, stroke size and tapping speed. We deliver including lubrication systems according to customer’s requirements.

more information

Wide range of backing sheets, planchettes and high precision sheets in various types of steel, copper and zinc alloy. Many thicknesses and widths to choose from. Hardness up to 60 HRC. Cold rolled in high precision. We also supply non-standard sizes and dimensions according to drawings.

more information

more information