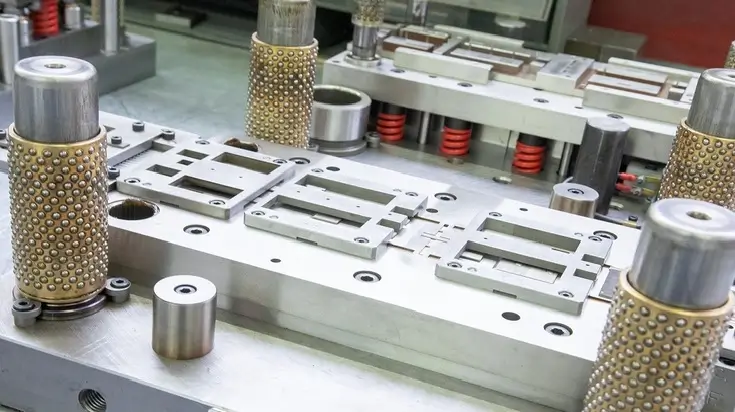

During the second half of 2016, we successfully launched our production of standardized punches, die buttons and parts according to drawing documentation at our headquarters in Žďár nad Sázavou. Thanks to the latest available technologies and the creation of a complete stock of semi-finished products, we now deliver according to customer requirements within 24 hours. We have in our warehouse semi-finished products of punches and ejectors according to ISO 8020, DIN 9861 and DIN 8977. All semi-finished products pass through our measuring centre where the dimensions and hardness are checked. Thanks to the above, we deliver in the same quality and within a tolerance of thousandths with a surface finish of up to 0.2 Ra. Our production is therefore unique not only in terms of the range of standardized parts we offer, but also because of its speed and flexibility. Our punches and die buttons meet NAPMA, NAAMS standards and are interchangeable with other competitive global brands in the market. We are able to produce any shear shape to the most demanding requirements. We also produce mould cores from ejector moulds which we also stock. We provide all available coatings on the market if component coating is required. Our company’s facilities are equipped with brand new machines that allow us to do turning, EDM wire cutting, EDM burn through of start holes, 5 axis CNC grinding, flat grinding and many other operations.

In addition to standardized parts, we also supply precise components according to the drawing documentation. Whether it is shear bars, dies, cores, form inserts, form plates, complete mould and tool frames, special applications according to drawings. Material, machining, surface finishes and any coating of parts are carried out according to customer requirements. Precision in thousandths is not a problem for us. Thanks to the state-of-the-art technology we have acquired, we are able to meet the most stringent quality and precision requirements.

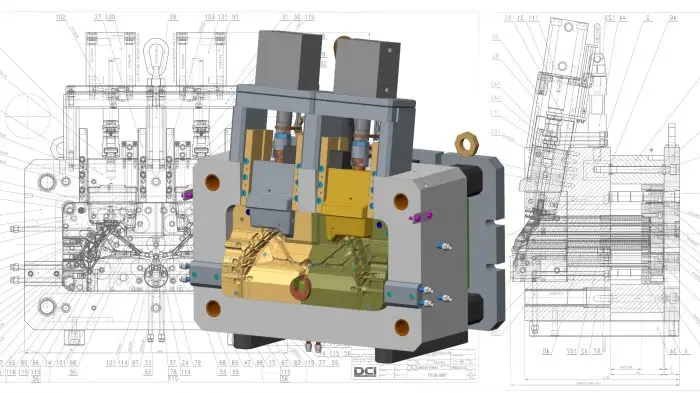

Our design office dealing with 3D and 2D design of molds and cuts for die casting of aluminum (Al), zinc (Zn) and magnesium (Mg) alloys THIXOMOLDING designs an efficient solution using the unique simulation software FLOW-3D Cast. We have more than 20 years of experience with the development of castings from Al, Zn, Mg alloys and tools.

With our own products and with the products of our partners that we represent, we are accredited and proud suppliers of automotive groups Daimler (Mercedes, Smart), FCA (Alfa Romeo, Dodge, Fiat, Chrysler, Jeep, Lancia, Maserati), Ford, Geely (Geely, Volvo), GM (Buick, Cadillac, GMC, Chevrolet), Hyundai (Hyundai, Kia), Nissan (Datsun, Nissan), PSA (DS Automobiles, Citroen, Opel, Peugeot), Renault (Dacia, Renault), TATA (Jaguar, Land Rover, TATA Motors), Volkswagen Group (Audi, Bentley, Bugatti, Lamborghini, Man, Porsche, Seat, Škoda, Scania, Volkswagen), jejich vážených subdodavatelů a dalších světových výrobců dle norem ISO, VDI, DIN, NAAMS, AFNOR, JIS, IATF.

We have decided to add new machines to our production fleet. We have purchased a centerless NC grinder for the modification of punch shanks and an NC surface grinder for the modification of locking surfaces of die buttons and other products.

Thanks to more efficient internal processes and recovering markets, we achieved the second best result in the company’s history. We focused on our measurement center. We purchased new technology to measure faster and more accurately. We are now fully equipped for 2D and 3D output inspection of our products, which we are able to supply including a measurement report.

Vertical warehouse towers have been implemented for our main warehouse and the semi-finished goods warehouse for production. We implemented this hardware into our internal system and created a new logistics process that streamlined and accelerated the activities of all departments in the company. We also reduced errors by introducing barcodes on individual products.

As a result of the COVID-19 pandemic, the production of individual automotive companies has declined worldwide. Following the shutdown of production lines and the suspension of new projects, the activities of subcontracting chains were severely curtailed. This situation has also affected our company. Thanks to internal measures, reductions in operating costs and the dedication of all employees in the company, we have coped with this situation very well. We reacted early to the cooling of the markets and believed that this situation must improve in the shortest possible time. The year 2020 was a year of making savings and finding new solutions in our internal production processes and our warehouses so that we are prepared for similar situations in the future.

Due to the situation in the automotive industry this year, we were forced to slim down the company. A lot of activities were cumulated within our company. Processes have been initiated to make all activities in the company more efficient and to speed up daily activities towards our customers.

Thanks to the processes of refinement and greater efficiency in our production and the strong growth in automotive volumes, we have been able to increase our cumulative company turnover above EUR 6 million.

This year, we made efforts to develop our marketing activities in the market. So that we can fully develop our efforts that we have put into new production processes and technologies in the past years. We have increased the activities of our sales force and streamlined our cooperation with our customers.

We started our own production in our company. We have purchased individual technologies for the complete production of cutters and dies so that we can meet the needs of our customers within 24 hours. We significantly increased our turnover in components as per drawings. We were able to establish long-term cooperation with our partners in this sector.

We have decided to go the custom manufacturing route. In this year we started to prepare and create technological procedures for our future production in our country. A new inventory system was created according to the turnover of each component. There was an increase in inventory and subsequent cumulative management of this process.

Since 2017, our company has been supporting triathlete Kateřina Mičková, who is currently included in the Czech Republic’s junior national team.

In recent years, Kačka has become a multiple Czech Republic Champion and the overall winner of the Czech Cup. She studies and trains in Žďár nad Sázavou.

However, we firmly believe that Kačka’s greatest sporting successes are yet to come.

At the moment we are not looking for anyone to join our team.